Preflight Assessment

This page covers Task A. Preflight Assessment from the FAA-S-ACS-25 Flight Instructor for Airplane Category Airman Certification Standards.

Pilot self-assessment

- Use the IMSAFE checklist

- I - Illness

- M - Medication

- S - Stress

- A - Alcohol

- F - Fatigue

- E - Eating / Emotion

Determining that the airplane to be used is appropriate and airworthy

- Check required inspections have been met and perform a preflight inspection

Airplane Preflight Inspection

- Reasons for the preflight inspection, items that should be inspected, and how defects are detected.

- The reason for the preflight inspection is determine that the aircraft is in proper condition before flying

- The POH/AFM provides basic guidance as to what to inspect

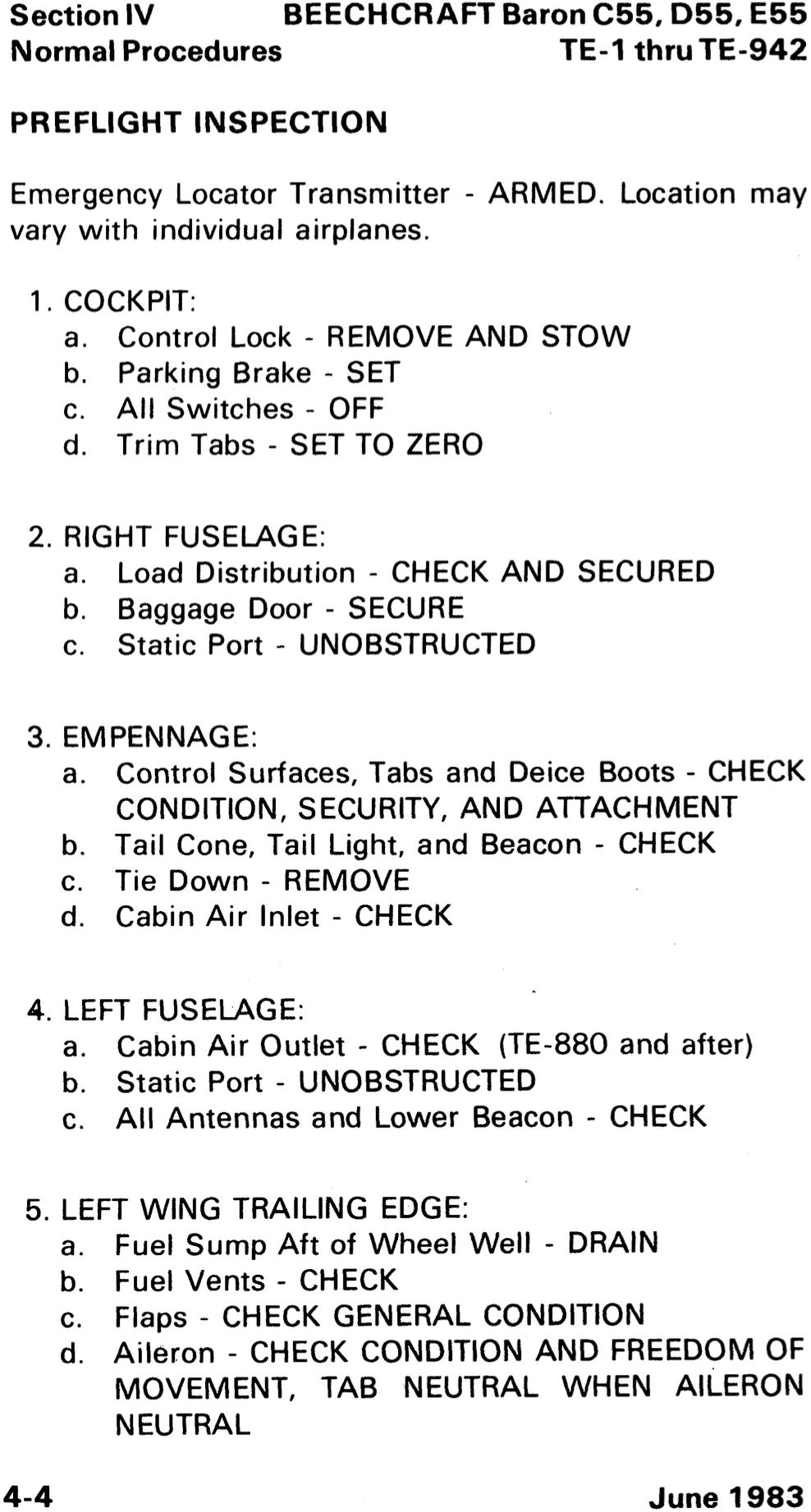

- See for example the POH page below

- The POH/AFM provides basic guidance as to how to detect defects

- For example in the POH page below, it indicates the adjective for the static port is "unobstructed"

- However, the POH/AFM is not at all comprehensive when it comes to describing what is and is not normal, and how to detect defects

- Much of this information comes from other sources, including manufacturer maintenance or shop manuals, FAA documentation, guidance from an A&P, and more

- The guidance in the POH/AFM should serve as the floor rather than the ceiling in terms of what to inspect -- the PIC should feel empowered to inspect above and beyond the minimum required should they so choose

- When in doubt, double check

- It is far better to take time while on the ground to do a bit of research, make some phone calls in order to determine whether the condition of something indicates a defect, or is normal

- In the end the PIC is still responsible for determining aircraft airworthiness

- In addition, different equipment may have been installed that requires preflight inspection that is not described in the POH/AFM

- Importance of using the appropriate checklist.

- The use of checklists during preflight is imperative to make sure no checks are overlooked, missed, or performed incorrectly

- Most aircraft checklists provide guidance in addition to and beyond the minimal guidance in the POH/AFM to ensure a correct and thorough inspection consistent with manufacturer guidance

- Often guidance in these checklists is more conservative than that specified by the manufacturer

- For example, requiring minimum oil levels above the manufacturers minimum oil level

- How to determine fuel and oil quantity and contamination.

- Fuel quantity must always be checked by visual inspection

- Make sure fuel gauges and fuel quanity set in engine management system match

- To determine fuel quantity at levels other than full, or those marked by the manufacturer in some other way (e.g. filler neck, tab) do not eyeball it -- get a fuel stick and measure it

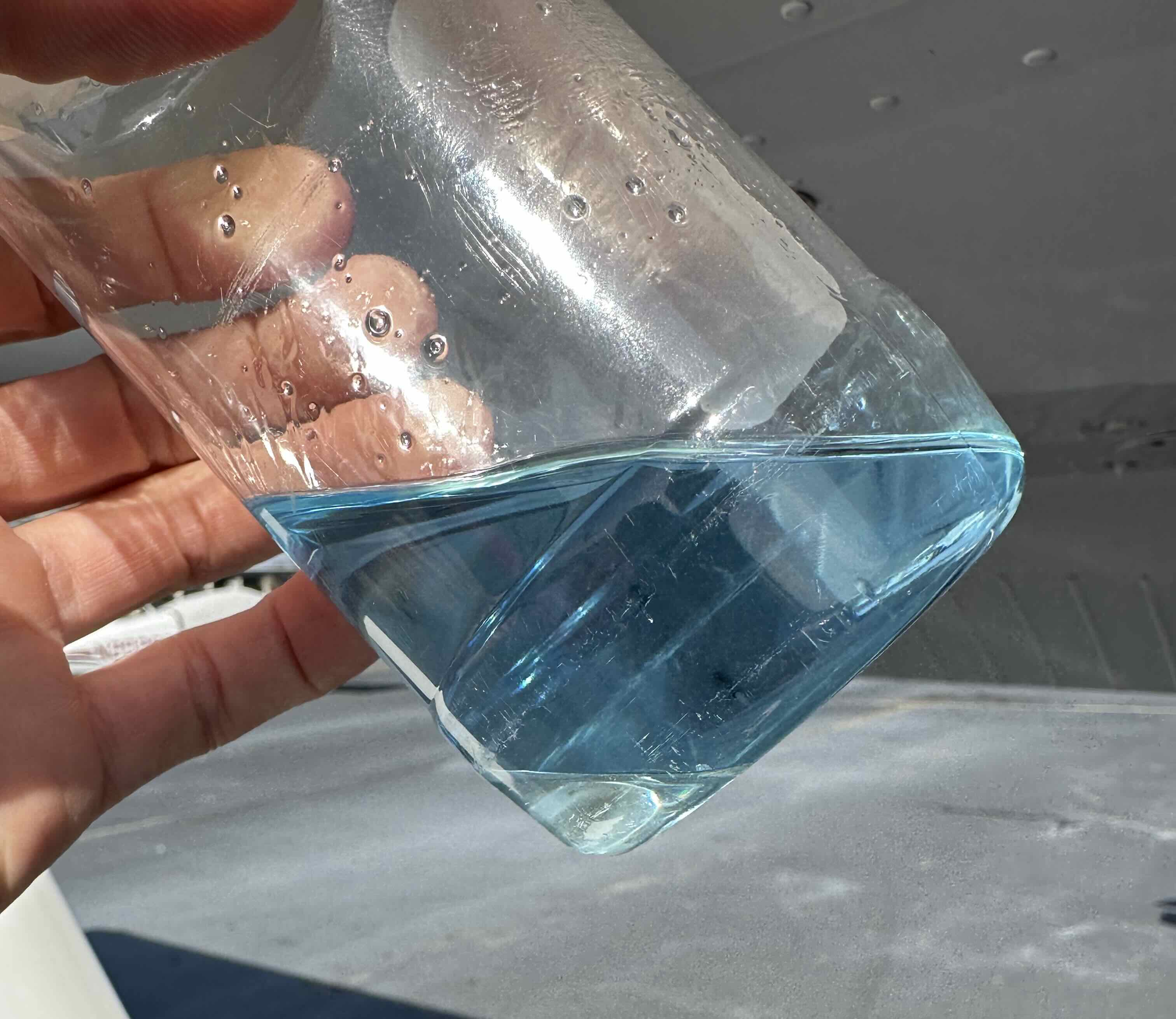

- Fuel quality is best determined from the fuel sample obtained when draining the fuel sumps

- Check the color of the fuel to make sure it is correct, and that there is no water or particulate matter in the fuel

- Oil quantity must always be checked using a visual inspection of the level indicated on the dip stick

- Wipe the dip stick if needed to get a clear indication

- Oil quality is best determined by visual inspection of the oil on the dipstick

- Fuel quantity must always be checked by visual inspection

- Detection of fuel, oil, and hydraulic leaks.

- The first thing is to know the various systems on your aircraft to know where various fluids should be present, and thus where to look for leaks

- Know the colors of different fluids

- Fuel: blue

- Oil: amber to brown to blacker with age

- Hydraulic: red

- Visually inspect various places where leaks may occur during preflight

- Prop

- Brake lines and calipers

- Sumps

- Perform additional checks prior to takeoff to make final determination of leaks

- Check pressure of brakes before engine start

- Look for oil leaking from props after cycling them during runup

- Inspection of the oxygen system, including supply and proper operation (if applicable).

- N3622A used for the MEI checkride does not have an oxygen system

- Inspection of the flight controls and water rudder (if applicable).

- Inspect to the extent practicable during the preflight inspection

- Areas to inspect

- Control surfaces

- Control linkages and cables

- Hinges and fasteners

- Detection of visible structural damage.

- Planes like the Baron and many other trainers are semimonocoque construction, where the skin plays a role in the structure of the aircraft

- Inspect the exterior of the plane for damage to the skin, rivets, and other structural components

- Damage to the structure could lead to breakup of the aircraft during flight

- Removal of tie-downs, control locks, and wheel chocks.

- While these things might be obvious, they can be easily forgotten

- Use of checklists helps prevent this

- Also use a final 360 degree walk-around to make a final check of important things like this that are easy to forget

- Tiedowns removed

- Chocks removed

- Cowl plugs removed

- Pitot cover removed

- Fuel caps on

- Removal of ice and frost.

- All ice and frost must be removed before flying

- Do not assume a little bit is acceptable, as even small amount can have an adverse affect on aicraft performance

- Remove ice and frost in a way consistent with manufacturer guidance, making sure not to damage the aircraft

- Some common methods include

- Brush to remove snow

- Alcohol spray

- Turning the aircraft to face the sun and let it melt

- Importance of the proper loading and securing of baggage, cargo, and equipment.

- The two main resons for loading and securing baggage, cargo, and equipment are

- Make sure the balance of the aircraft does not change in unintended ways during flight

- Prevent injury to the occupants or damage to the aircraft if cargo shifts during flight

- The two main resons for loading and securing baggage, cargo, and equipment are

- Use of sound judgment in determining whether the airplane is in an airworthy condition for safe flight.

- Follow all the guidance above

- When in doubt do not fly

- Gather more information if necessary to determine the aircraft is airworthy

Environmental Factors

- Including weather, terrain, route selection, and obstructions.