E55 Baron (Late) Systems

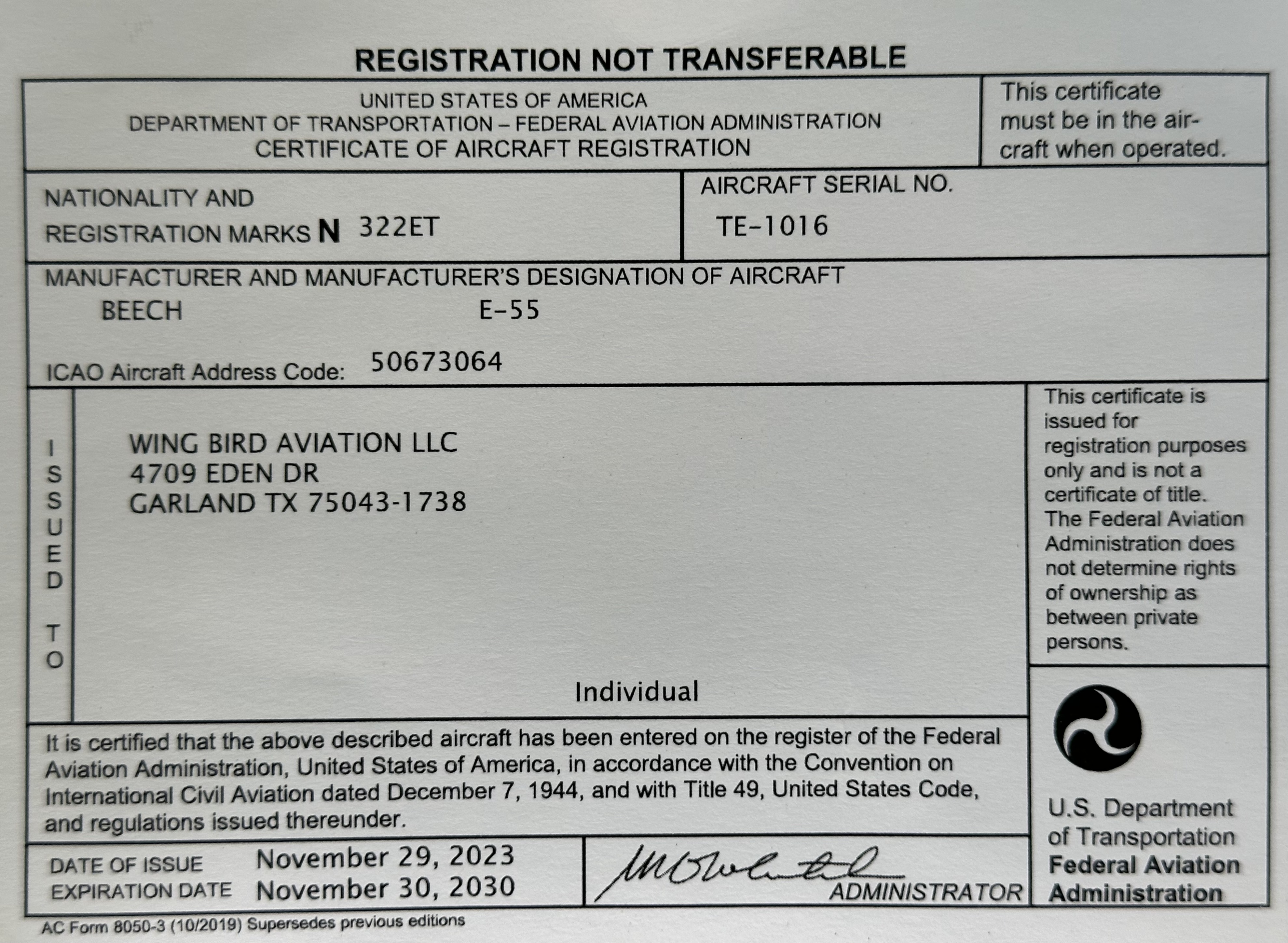

This document describes the systems on Baron N322ET.

Overview

- N322ET

- Serial TE-1016

- Model: E55

- Year: 1975

- Max takeoff weight: 5300 lb

- Max landing weight: 5300 lb

- The following sections cover all the systems as described in CFI ACS Part II Task E. Aircraft Flight Controls and Operation of Systems

Primary Flight Controls

- Electric trim on pitch axis only

- There is a separate breaker for pitch trim servo

Secondary Flight Controls

- Flaps

- Electrically actuated

- Positions

- 15° (Approach)

- 30° (Full)

- Slotted type

- POH page 7-7

- The switch must be pulled out of a detent to change the flap position

- Note: the flap position indicator on N322ET does not work

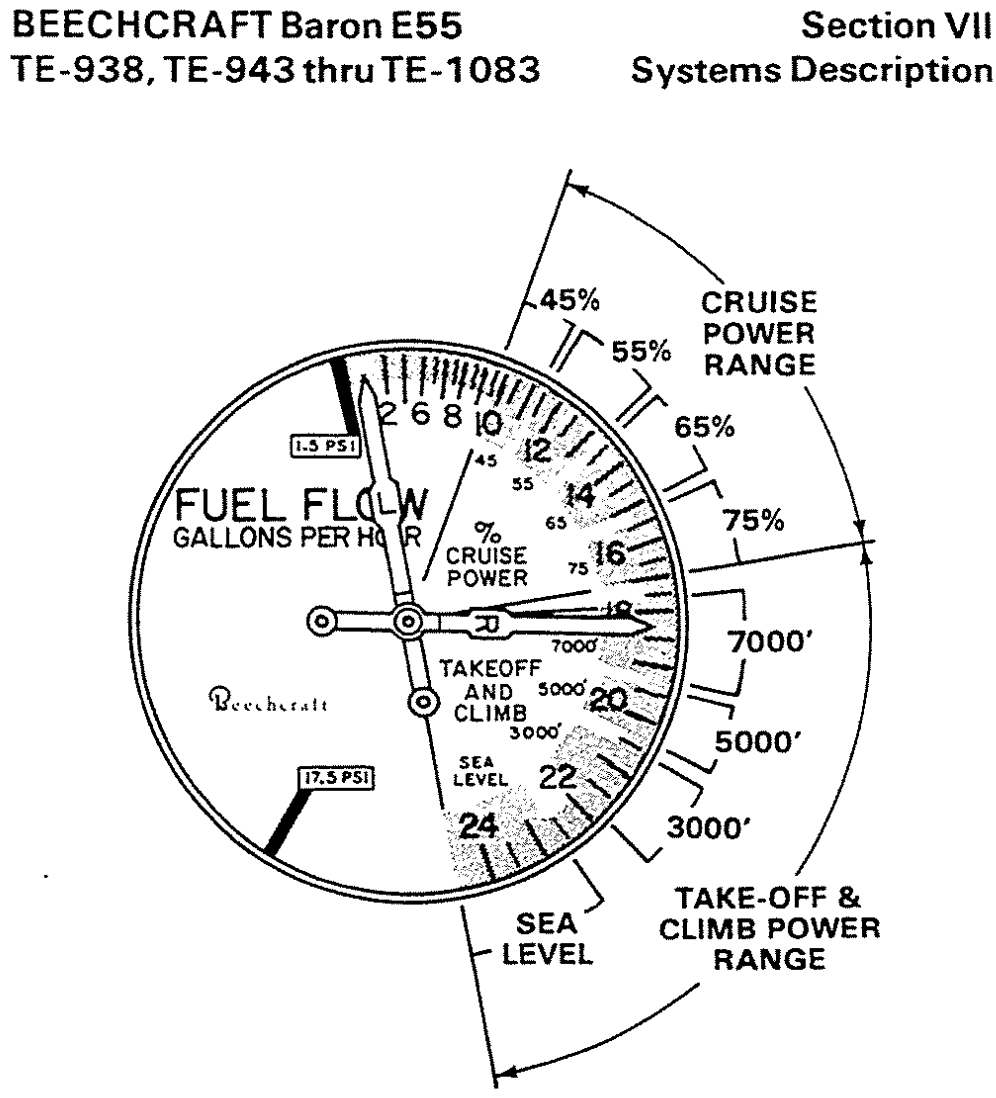

Powerplant and Propellers

- Engine Overview (CHAND)

- C - Continental IO-520-C

- Fuel injected

- Six-cylinder

- Rated at 285 horsepower at 2700 rpm

- H - Horizontally opposed

- A - Air cooled

- N - Naturally aspirated

- D - Direct-drive

- C - Continental IO-520-C

- Engine lubrication and cooling

- 12 quart oil capacity (page 7-25)

- No published minimum oil, Company policy is 9

- Minimum

- Has thermostat to control flow through oil coolers

- Oil type is SAE 50 (above 40 °C) or SAE 30 (below 40 °C)

- Cowl flaps manually actuated

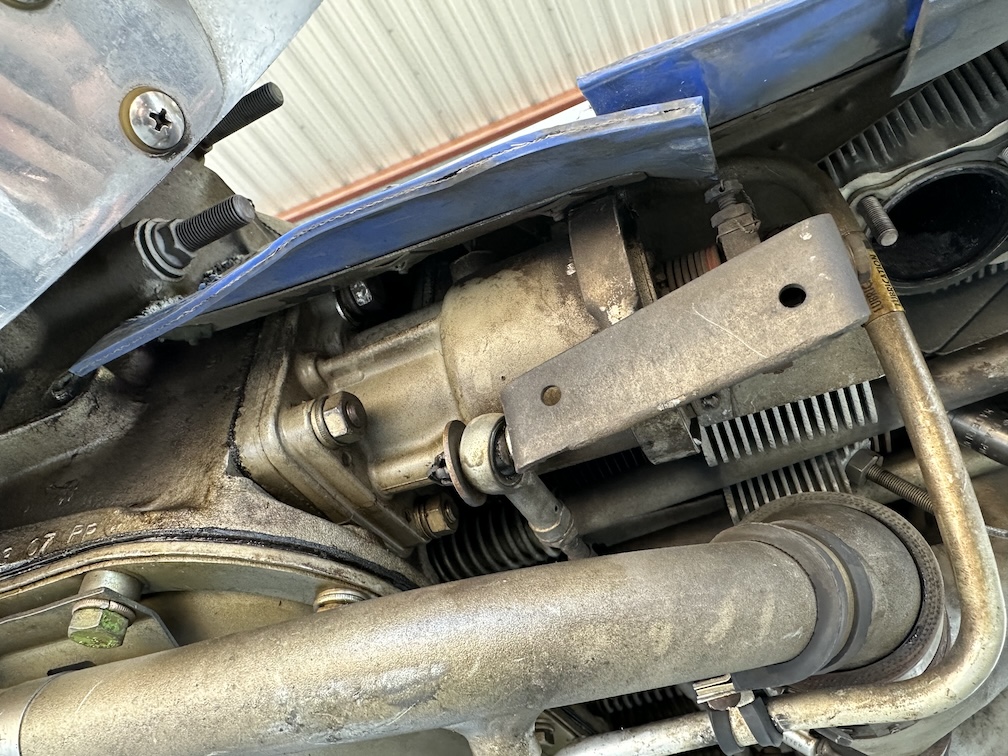

- The starter is located on the rear of the engine

- Induction System

- N322ET induction system draws air through the ram inlets and draws it through a filter

- Some Barons have an induction selector that allows for selection of filtered or unfiltered ram air

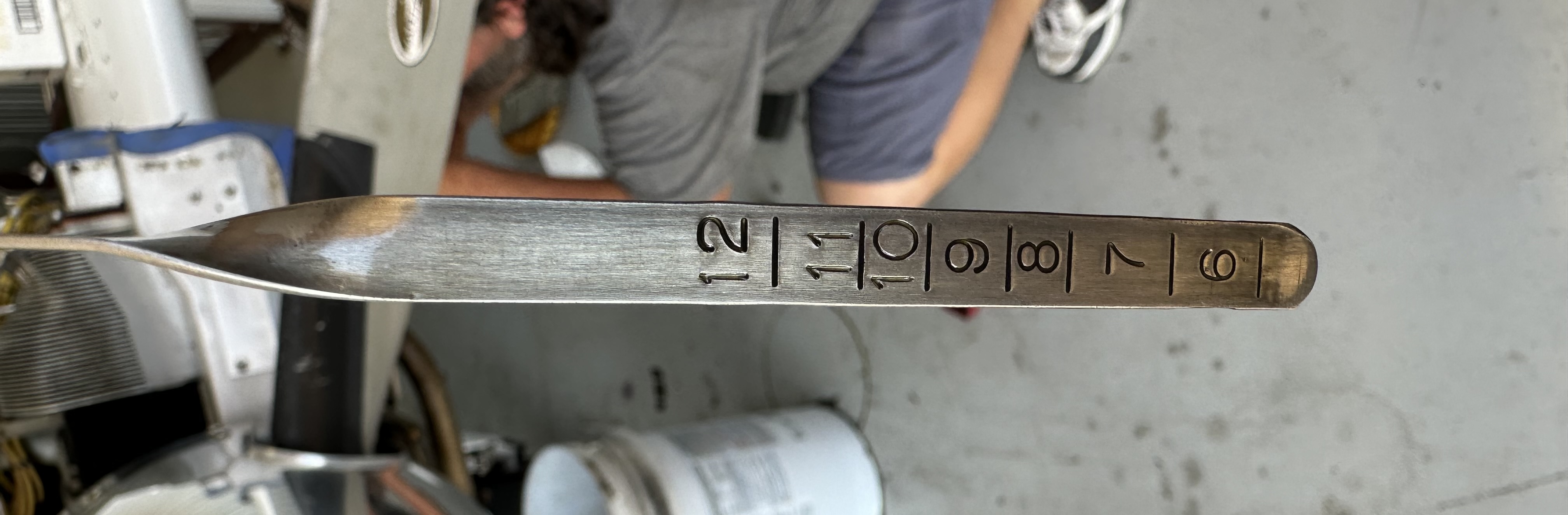

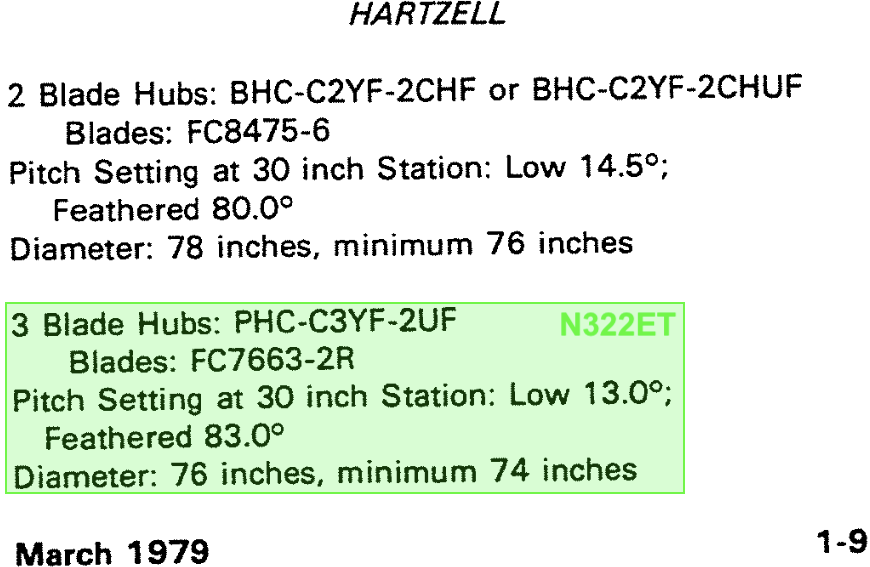

- Propeller system

- 3-bladed

- Hartzell

- P/N: PHC-C3YF-2UF

- 76 inch diameter

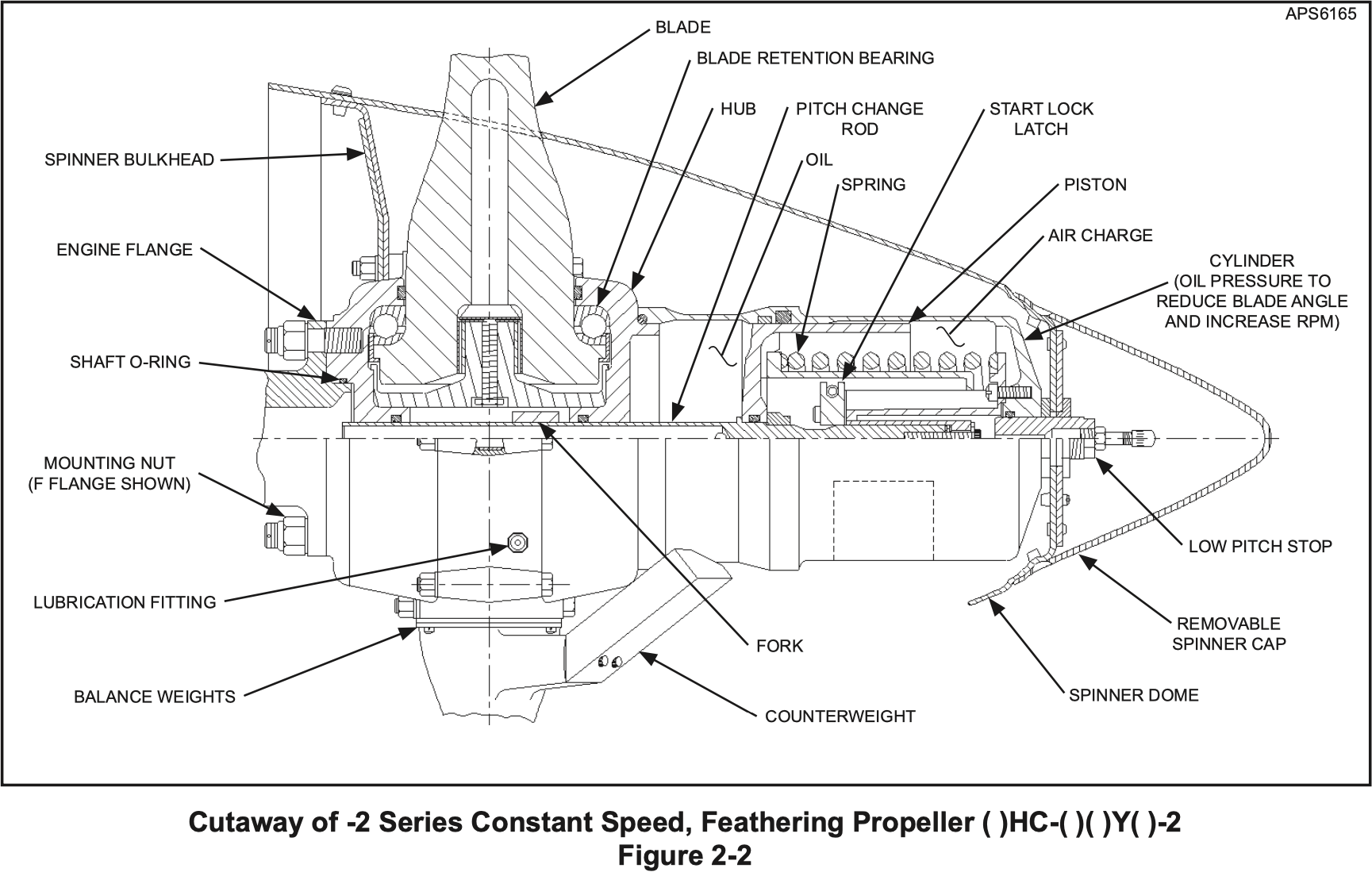

- Variable pitch

- Constant speed

- Full-feathering

- Forces moving prop to feather (high pitch)

- Springs

- Counterweights

- Air charge

- The air charge is not explicitly mentioned in the POH, but is in the prop guide for the propeller

- Engine oil under governor-boosted pressure moves the blades to low pitch

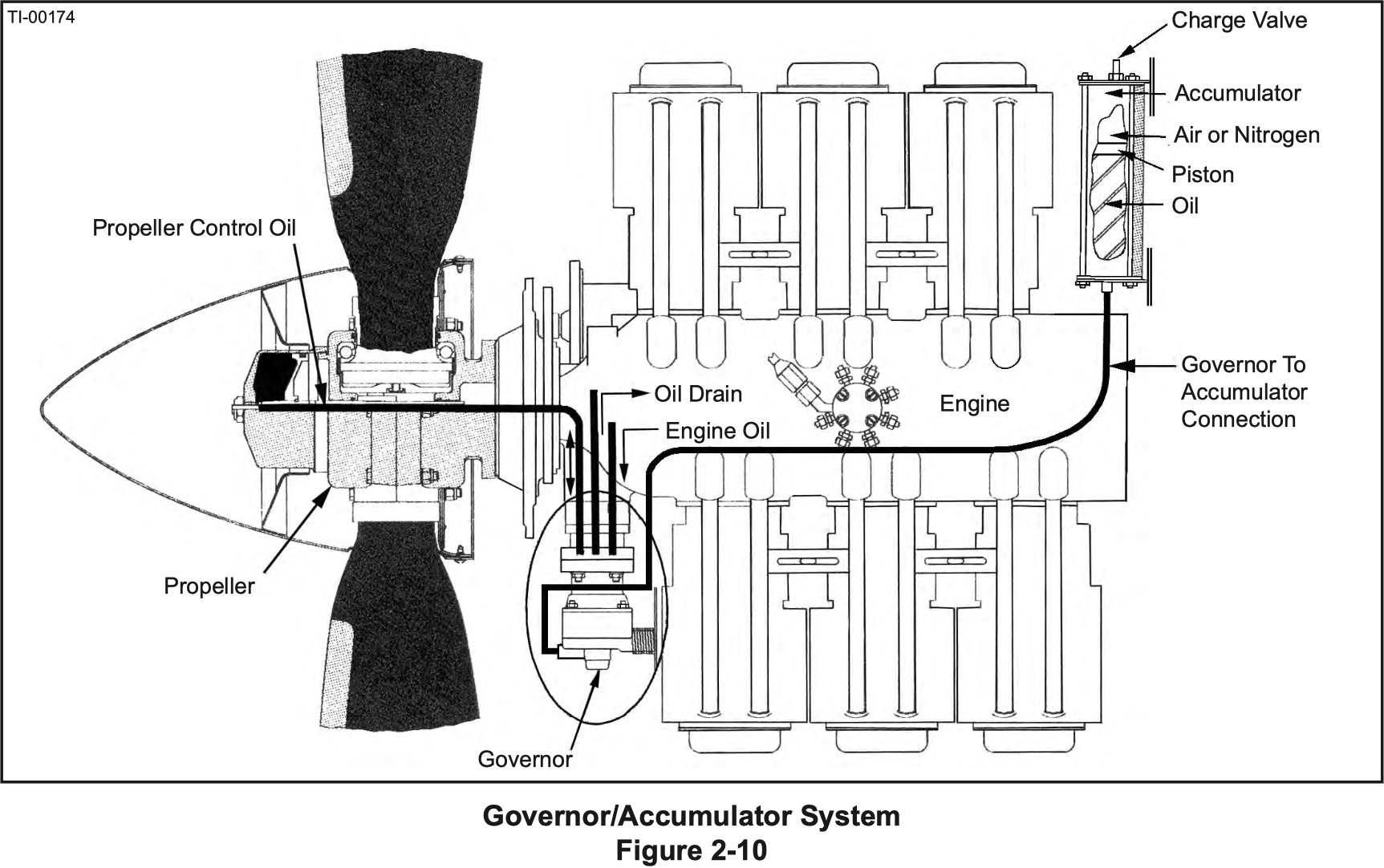

- Has unfeathering accumulators

- Gas-assisted pressure to drive oil back into the propeller dome to get the propeller on a stopped engine (that isn't producing oil pressure) out of feather

- Unfeathering accumulator like a balloon, when oil pump is going its blowing up the balloon

- Feather is pinching the balloon closed

- In prop big spring with nitrogen charge inside to push oil out

- Counterweights on prop to drive prop to feather

- POH page 7-20

- 3-bladed

Landing Gear

- Electrically actuated

- Squat switch on left main

- Additional squat switch on right main for logging flight time used for maintenance

- See https://www.csobeech.com/gear-rod.html for lots of gear mechanism pictures

- Gear

- Three gear down lights, one for each gear

- Gear lights dim when nav lights are on

- All three up switches in series = one red light?

- Gear extended closes the squat switch

- Gear has warning horn

- Hear it on short final, no hesitation -- go around immediately

- Amber light when in transit

- Nose gear has springs between rudder pedals and turning mechanism

- There is a button to test all the gear lights

- In N322ET the test light does not illuminate

- Landing gear warning horn does not work

Fuel, Oil, and Hydraulic

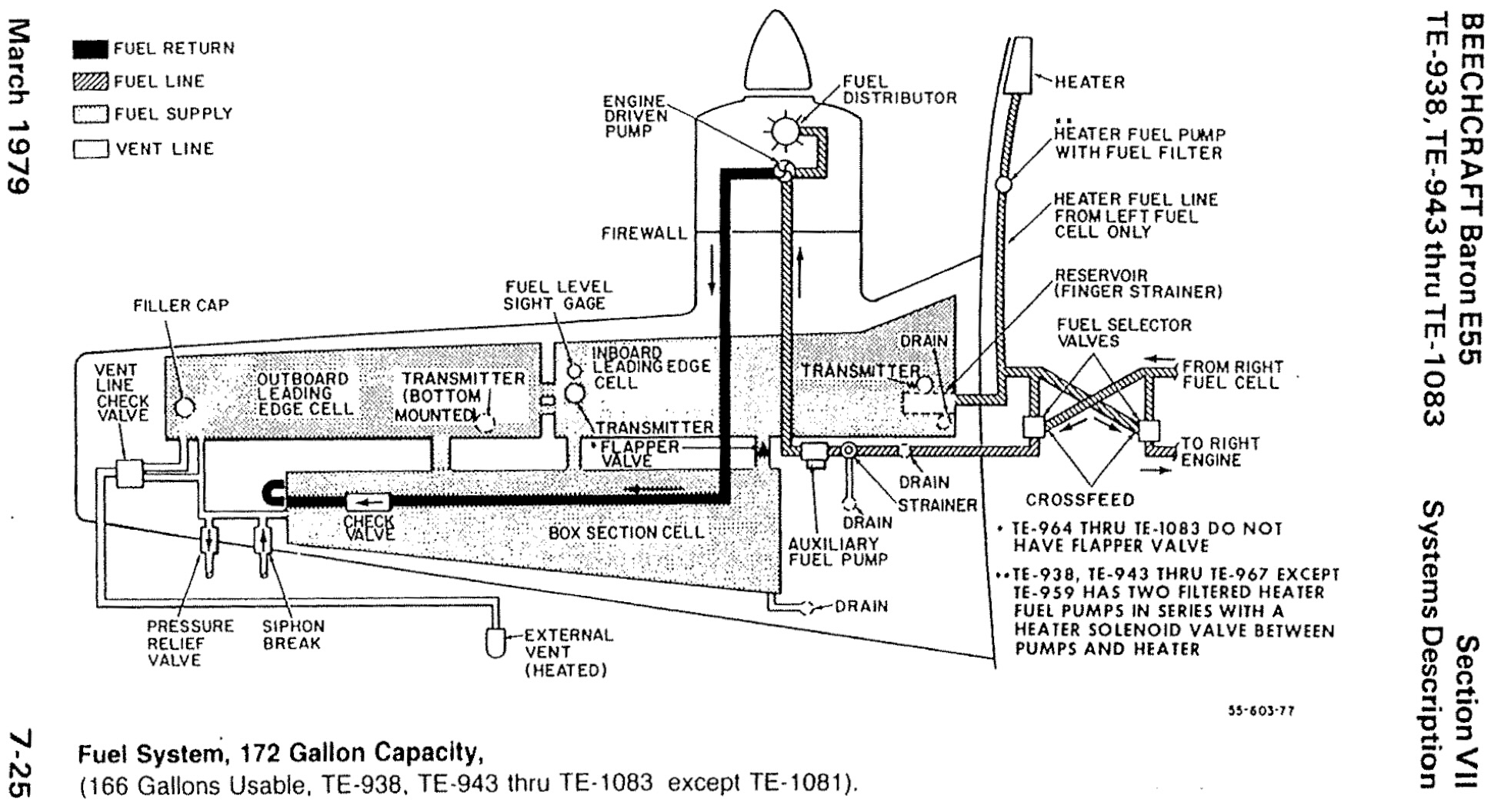

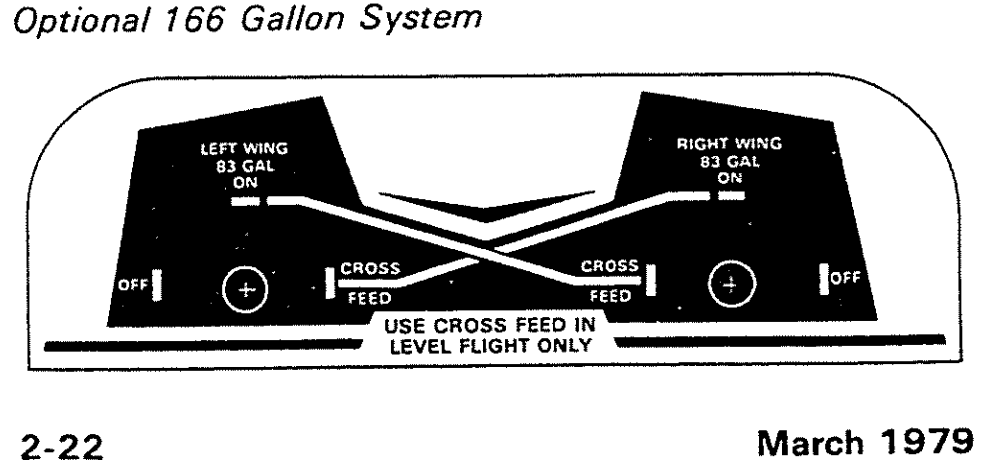

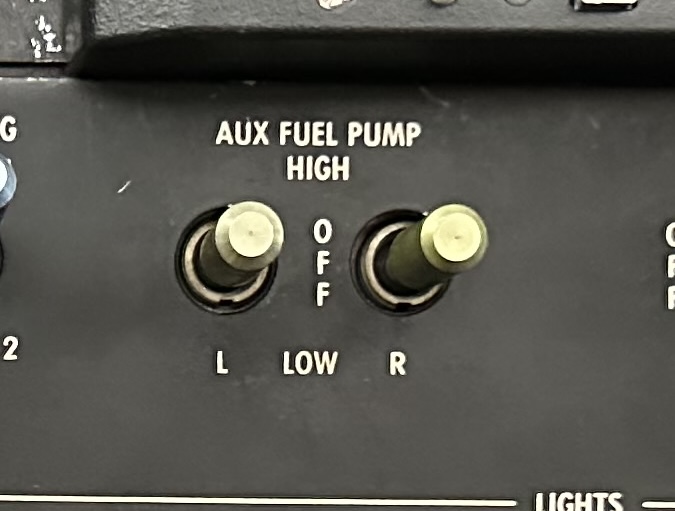

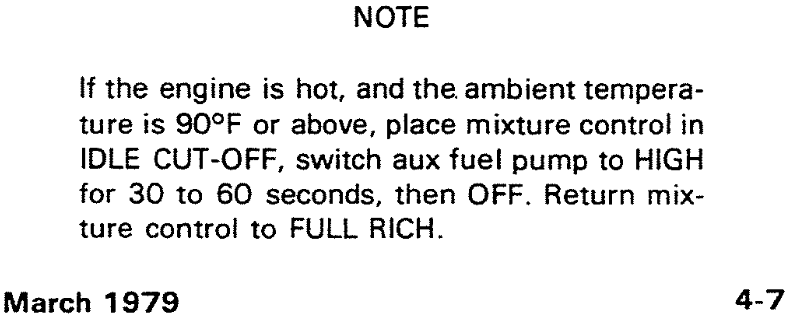

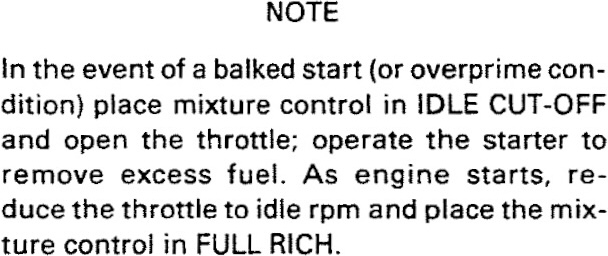

Fuel System

- Fuel capacity 172 gallons total, 166 gallons usable

- 4 sumps per side

- 1 for inboard cell, 1 for box cell, 1 for base of fuel line, 1 for strainer

- Fuel always returns to the tank on the same side as the engine

- Float type fuel sensors

- Note: in N322ET the fuel flow on right engine is a bit less than left when mixture handles are full rich

Oil System

- See above with powerplant

Brakes (Hydraulic)

- Do not leave the parking brake set when the plane is unattended

Electrical

- 24 volt electrical system

- Two 12 V lead acid in series

- Two 50-amp 28-volt gear driven alternators

- 2x full transistorized electonic voltage regulators

- Only one is active at a time controlling output of both alternators

- Other one is backup or standup

- One loadmeter for each alternator

- Stall switch is wired directly to the battery

- See POH page 7-29

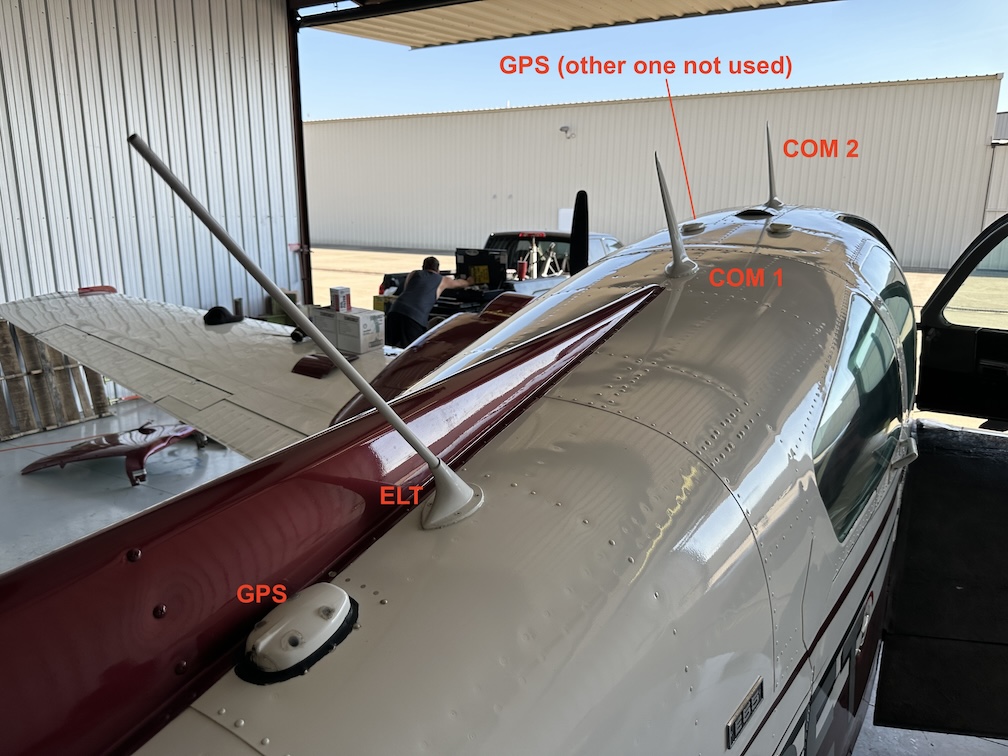

Avionics

- GNS 430W - com 1

- GNS 530 (no waas) - com 2

- Aspen Evolution flight display

- Attitude indicator

- Altimeter

- Airspeed indicator

- VSI

- HSI

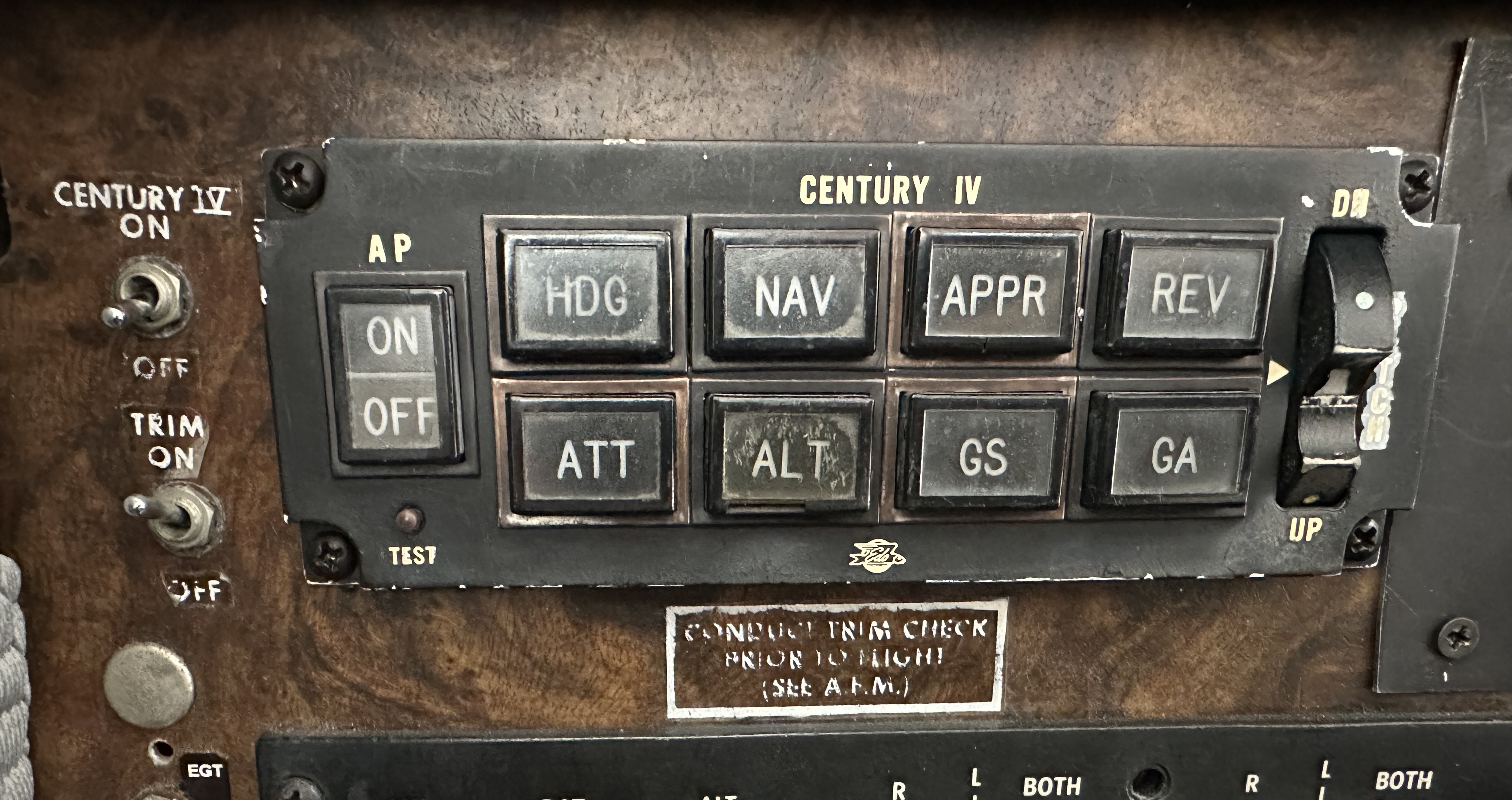

- Century IV autopilot

- Autopilot doesn't directly depend on pressure system

- But it draws info from the standby

- 2-axis autopilot - pitch and roll

- JPI EDM 790

- Has a synchroscope that is inoperative

Pitot Static, Vacuum/Pressure, and Associated Instruments

- One pitot tube on the nose

- Two static ports on left and right aft fuselage

- There is a positive pressure system that powers the standby attitude indicator

- Two engine-drive dry-pressure pumps

- If one pump fails, check valve seals it off and other one powers system

- There are lights inside the pressure gauge indicating which of the pumps failed

- There is little filter for intake above the rear cylinder

- There is another filter behind the firewall

- Alternate static red lever left lever by pilot side left shin

Environmental

- Air Conditioner

- Controlled by Sofie dial

- Off

- Fan

- Gnd

- Med

- High

- If you just want fan only need one alternator

- To turn on AC need both alternators on

- To get AC on ground need at 1000 RPM on both engines to supply enough power

- If it overheats it will shut itself off automatically

- Intake for AC condensor under fuselage

- Controlled by Sofie dial

- There is vent on left rear fuselage to let air out of cabin

- Heater

- Cabin heat controls temperature

- Cabin air controls amount of airflow

- Reducing cabin airflow allows for warmer air, but reduction below half turns off the heater

- Pilot air controls airflow to the back seats via vents below the front seats

- Blower only works on the ground

Deicing and anti-icing

- Prop and windscreen anti-icing

- Pitot heat

- Heated fuel vent?

- We have ice lights

Oxygen System

- No oxygen system