E55 Baron (Early) Systems

This document describes the systems on Baron N3622A.

Overview

- N3622A

- Serial TE-777

- Model: E55

- Year: 1969

- Max takeoff weight: 5300 lb

- Max landing weight: 5300 lb

- The following sections cover all the systems as described in CFI ACS Part II Task E. Aircraft Flight Controls and Operation of Systems

Primary Flight Controls

- Electric trim on pitch axis only

- There seems not to be a separate breaker for pitch trim servo

Secondary Flight Controls

- Flaps

- Electrically actuated

- Positions

- 15° (Approach)

- 30° (Full)

- The switch must be pulled out of a detent to change the flap position

- Slotted type

- See POH page 7-7

- Note: on earlier serials, the flaps had a weird method of operation that allowed selection of flap angles between 15° and 30°, but N3622A does not; the flaps will move to the position selected on the flap handle.

Powerplant and Propellers

- Engine Overview (CHAND)

- C - Continental IO-520-C

- Fuel injected

- Six-cylinder

- Rated at 285 horsepower at 2700 rpm

- H - Horizontally opposed

- A - Air cooled

- N - Naturally aspirated

- D - Direct-drive

- C - Continental IO-520-C

- Engine lubrication and cooling

- 12 quart oil capacity (page 7-25)

- No published minimum oil, Company policy is 9

- Has thermostat to control flow through oil coolers

- Oil type is SAE 50 (above 40 °C) or SAE 30 (below 40 °C)

- Cowl flaps manually actuated

- Induction System

- N3622A induction system draws air through the ram inlets and draws it through a filter

- Some Barons have an induction selector that allows for selection of filtered or unfiltered ram air

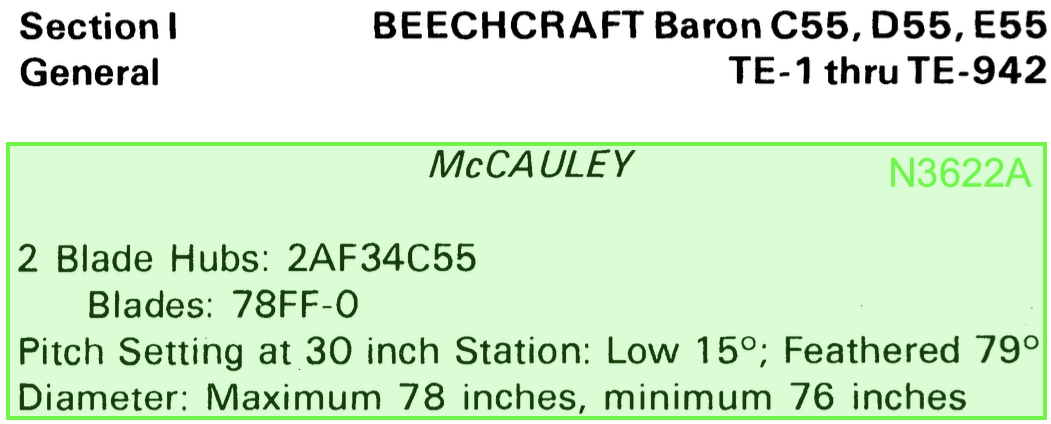

- Propeller system

- 2-bladed

- McCauley

- P/N: 2AF34C55

- 78 inch diameter

- Variable pitch

- Constant speed

- Full-feathering

- Forces moving prop to feather (high pitch)

- Springs

- Counterweights

- Air charge

- Engine oil under governor-boosted pressure moves the blades to low pitch

- Has unfeathering accumulators

- Gas-assisted pressure to drive oil back into the propeller dome to get the propeller on a stopped engine (that isn't producing oil pressure) out of feather

- Unfeathering accumulator like a balloon, when oil pump is going its blowing up the balloon

- Feather is pinching the balloon closed

- In prop big spring with nitrogen charge inside to push oil out

- Counterweights on prop to drive prop to feather

- POH page 1-12, 7-26

- 2-bladed

Landing Gear

- Electrically actuated

- Squat switch on left main

- See https://www.csobeech.com/gear-rod.html for lots of gear mechanism pictures

- Gear

- All three down and locked all three switches in series = one green light

- All three up switches in series = one red light

- Light bulbs you can rotate to dim for night

- Gear extended closes the squat switch

- Gear has warning horn

- Hear it on short final, no hesitation -- go around immediately

- Nose gear has springs between rudder pedals and turning mechanism

Fuel, Oil, and Hydraulic

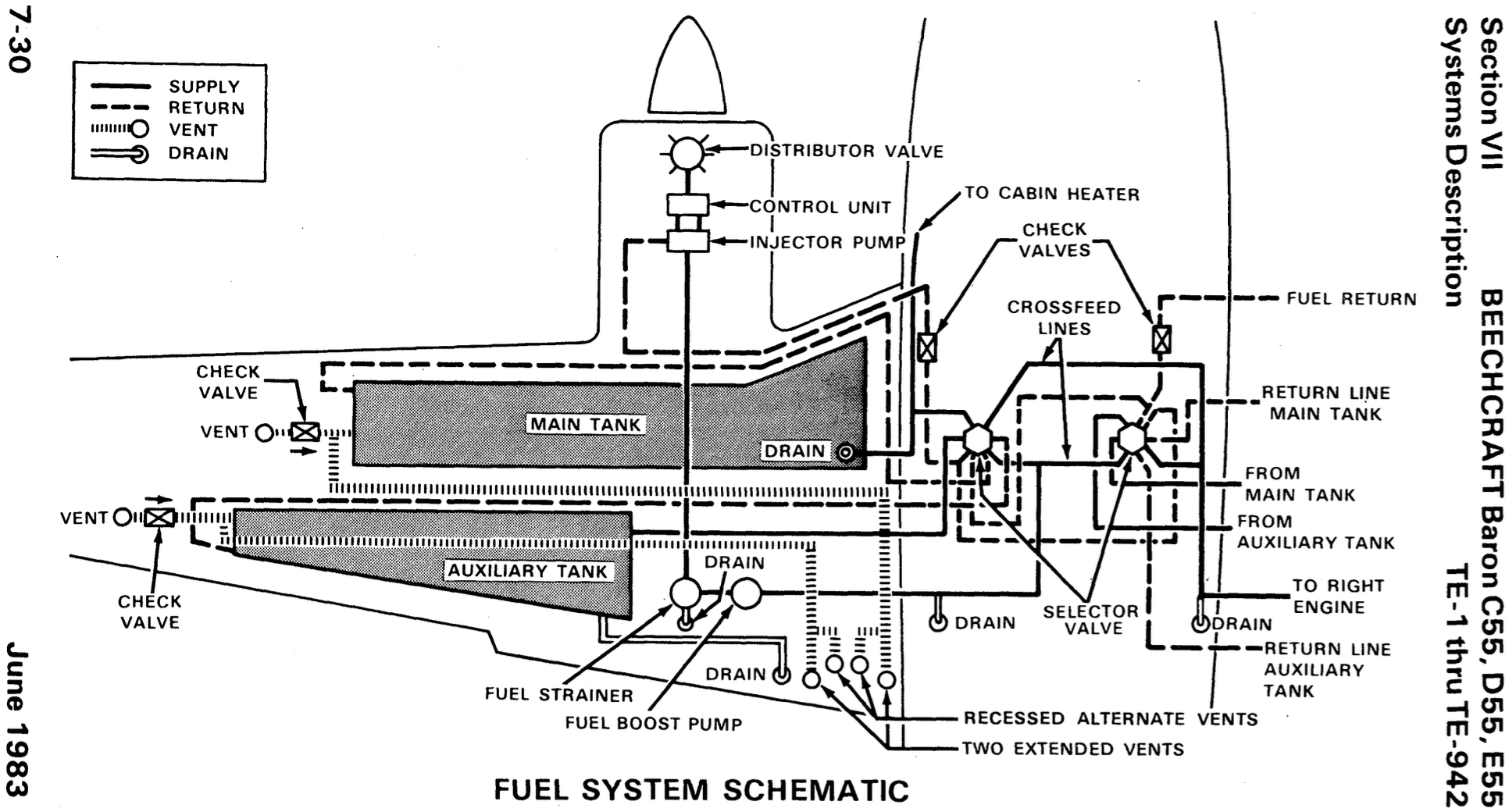

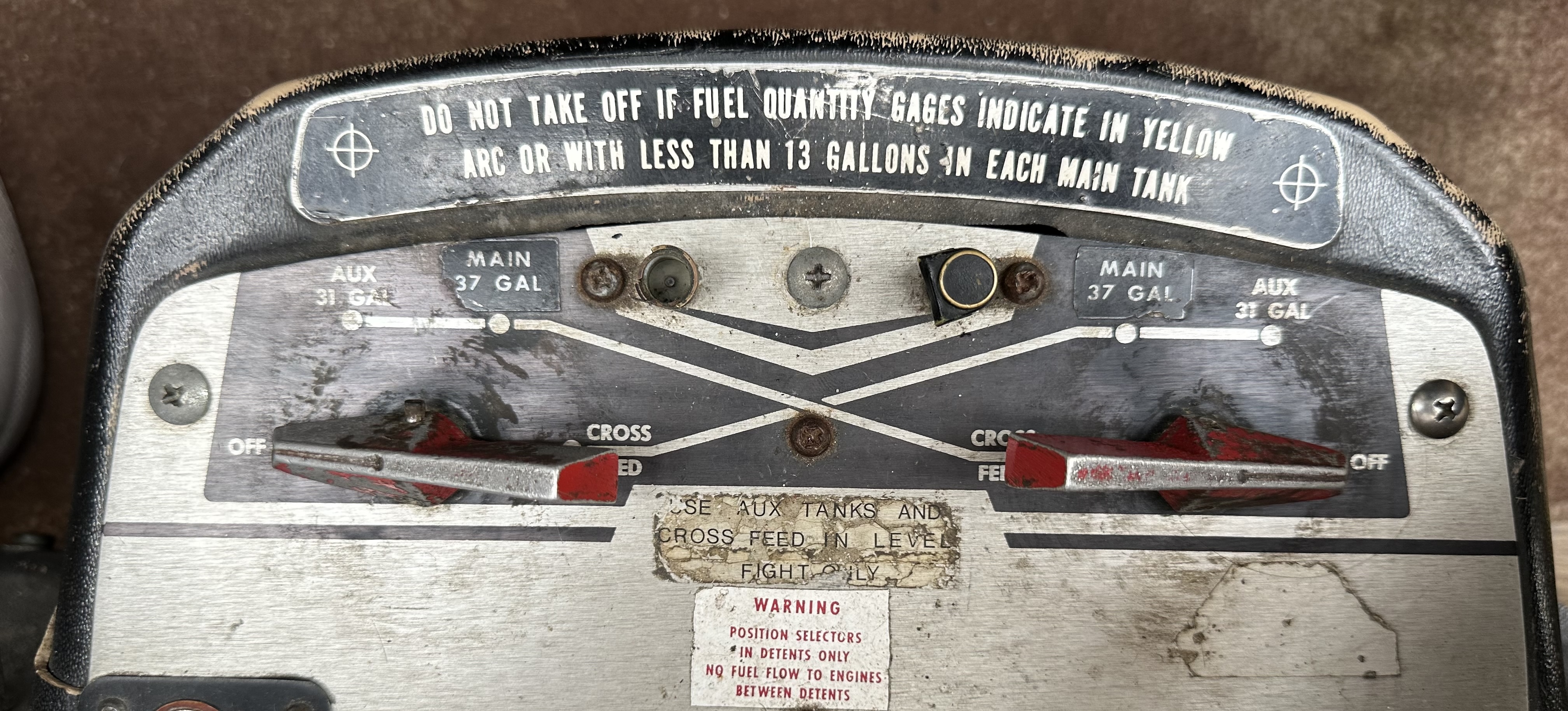

Fuel System

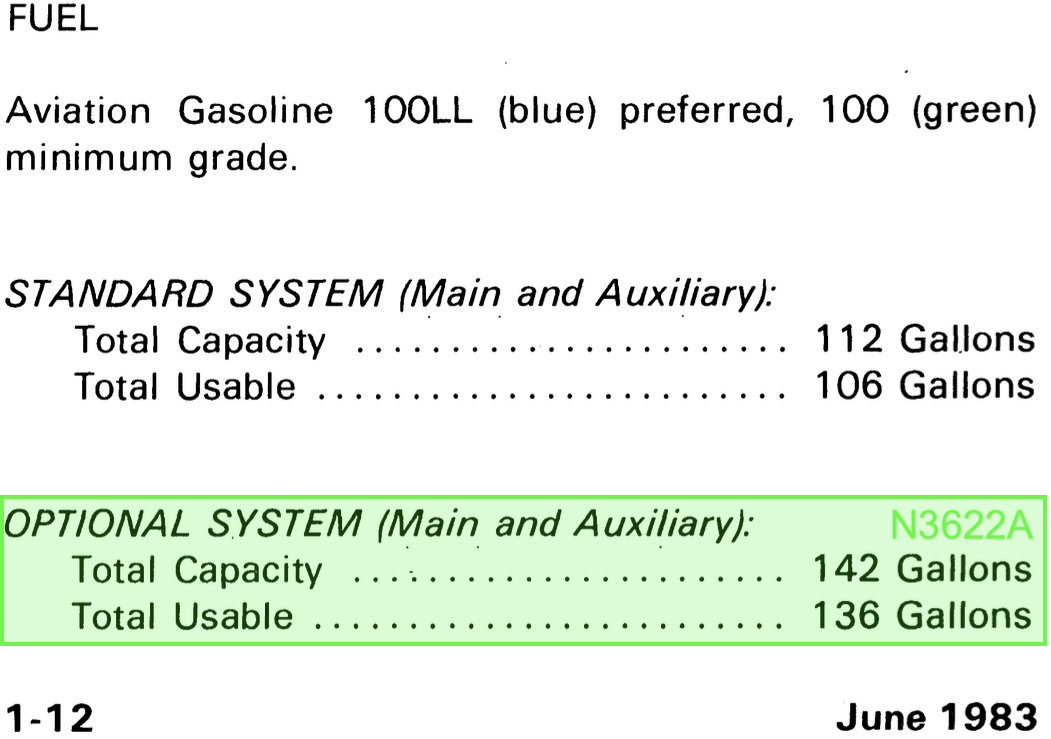

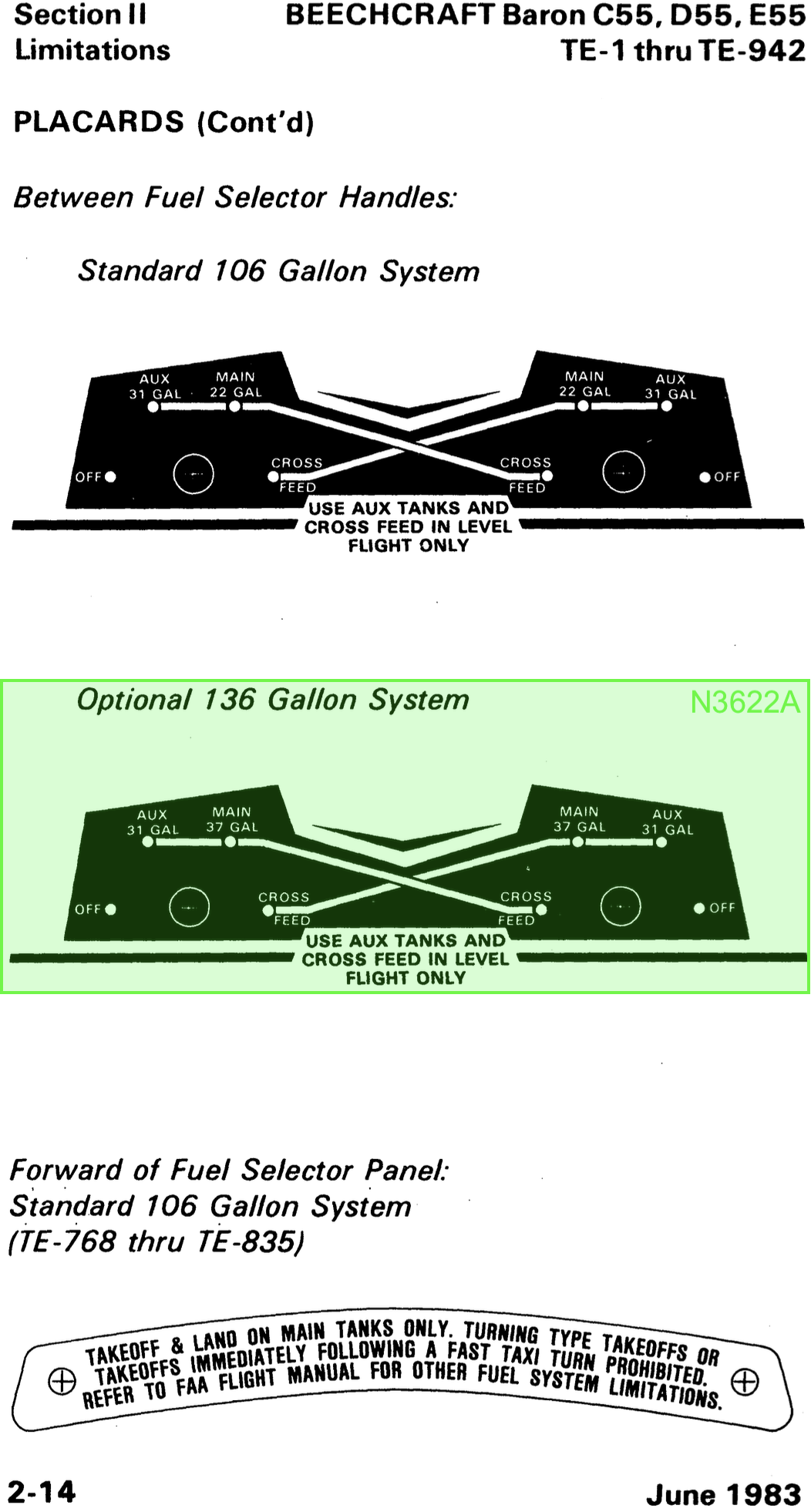

- Fuel capacity 142 gallons total, 136 gallons usable

- Mains 40 gallons total, 37 gallons usable

- Aux 31 gallons total (all usable)

- 4 sumps per side

- Main, aux, 1 for base of fuel line, 1 for strainer

- Fuel returns back to the tank that is selected

- Float type fuel sensors

Oil System

- See above with powerplant

Brakes (Hydraulic)

- Do not leave the parking brake set when the plane is unattended

Electrical

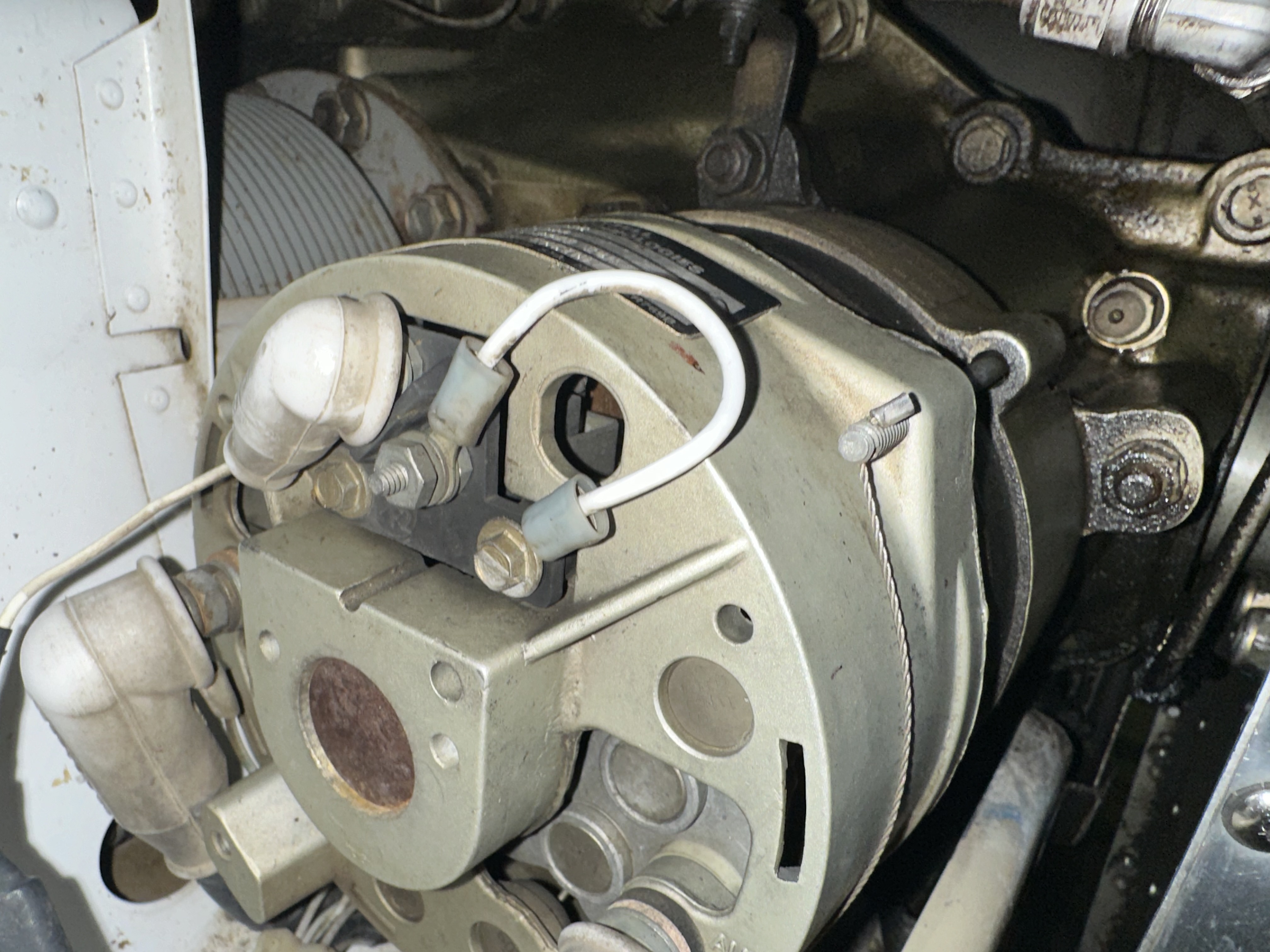

- 24 volt electrical system

- Two 12 volt batteries connected in series

- Two 50-amp 28-volt gear driven alternators

- There is a two-position voltage regulator switch

- Doesn't matter which voltage regulator is used

- In case of voltage drop, can try the other regulator

- See POH page 7-31

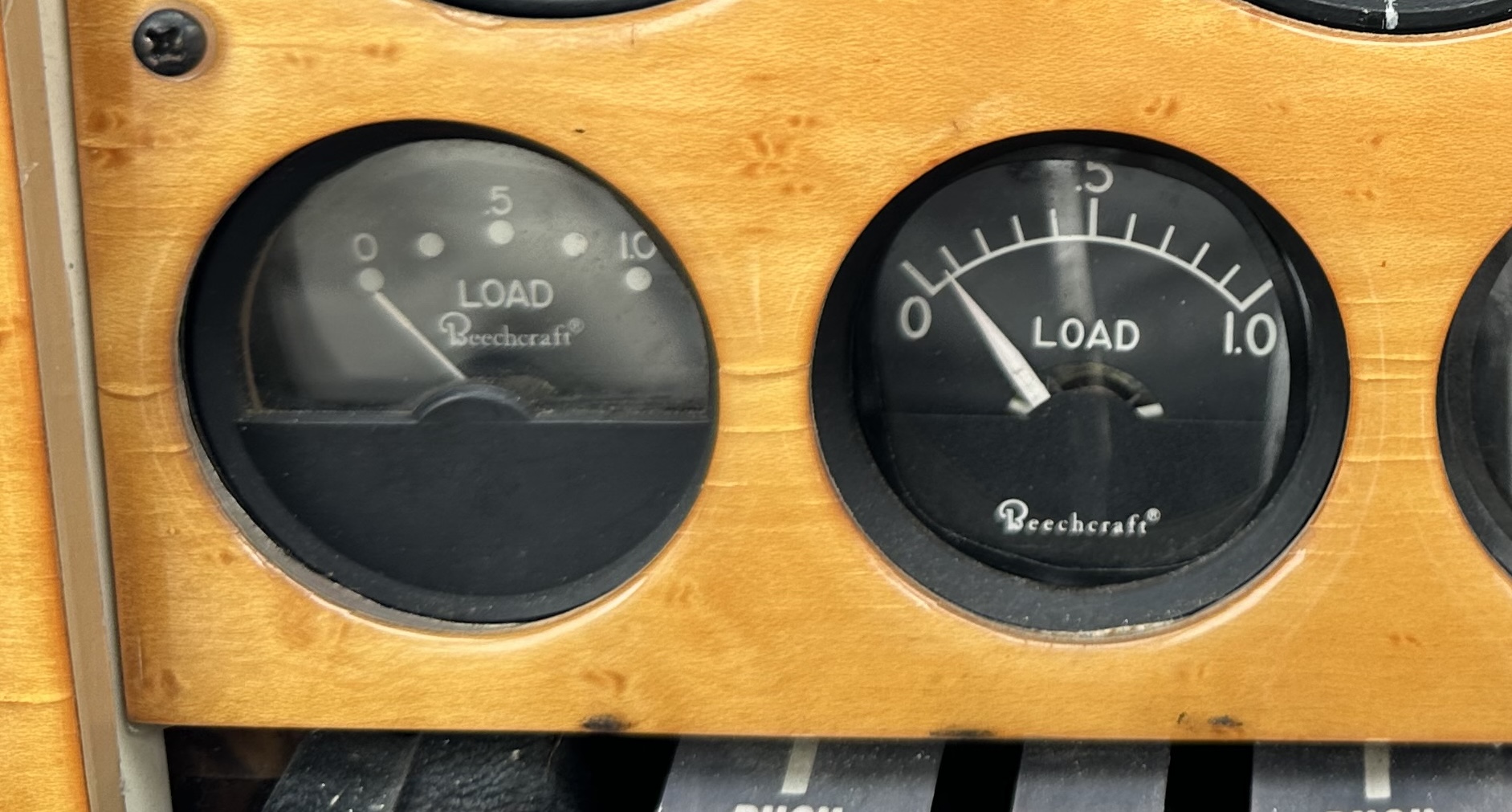

- Load meters

- Measure load on alternators

- Compare with ammeters which show how much the battery is being charged or discharged

Avionics

- GNS 530W - com 1

- GNS 430 (no waas) - com 2

- GFC600 Autopilot

- 2-axis - pitch and roll

- GMC 605 mode controller

- GI 285 annunciator panel

- With Control Wheel Steering (CWS)

- After the autopilot test, two presses to kill the autopilot and on the third press hold it down until you see ESP OFF (Electronic Stability Protection)

- Note: "If the AP DISC / TRIM INT button is held down for 5 seconds or more, ESP will be disabled. ESP will be re-enabled when either of the AP or FD keys are selected on or power is cycled on the GMC 605."

- Has internal AHRS

- PM2000 Intercom

- Garmin GTX 330ES Transponder

Pitot Static, Vacuum/Pressure, and Associated Instruments

- One pitot tube under left wing

- Two static ports on left and right aft fuselage

- No vacuum or pressure system or instruments

- Alternate static red lever left lever by pilot side left shin

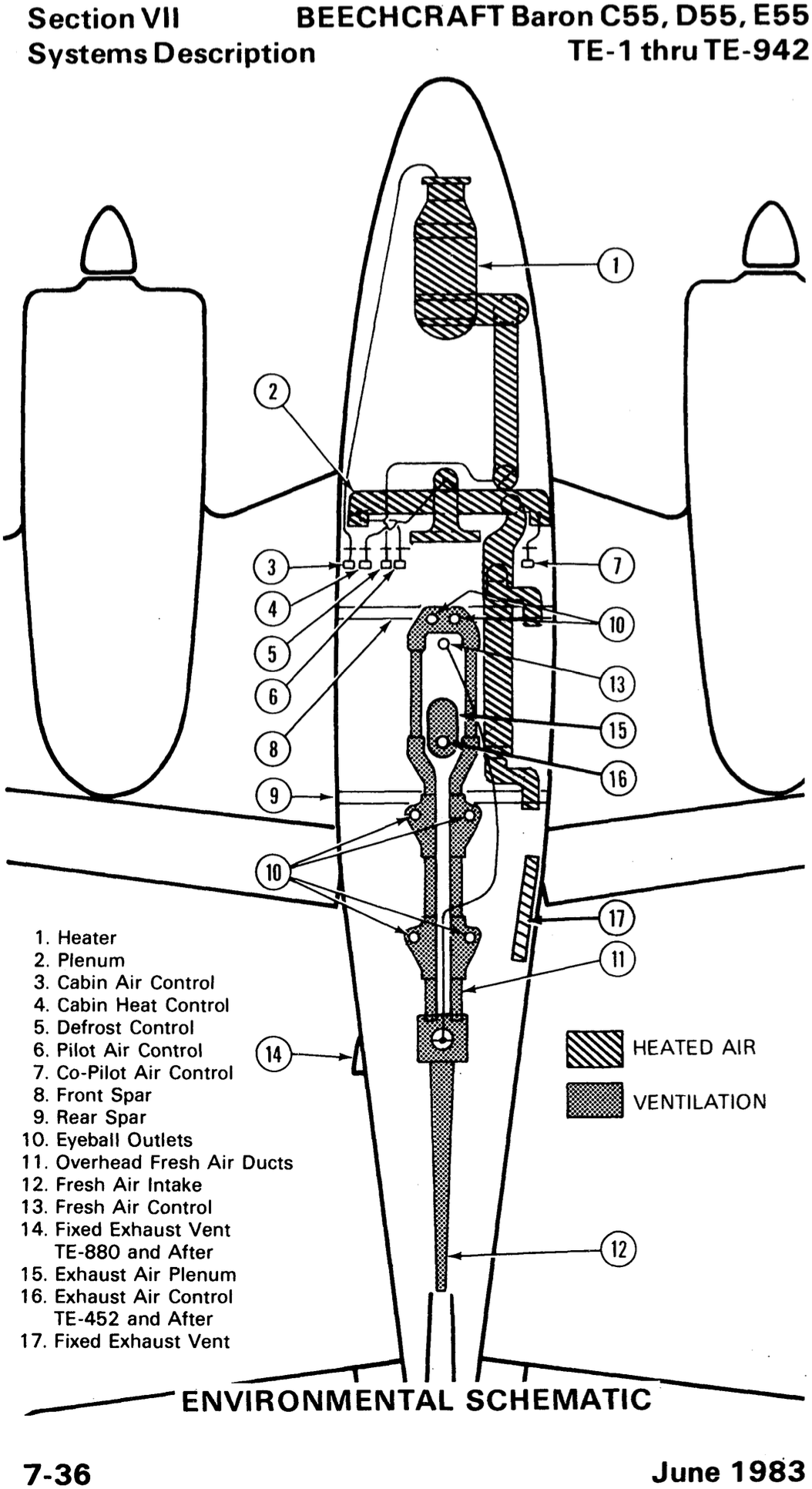

Environmental

- Heater burns from left main

- 0.5 - 1 gph (find reference for that)

- 25 Amp hour, 12 V lead acid connected in series = 24 V system

- Controlled by two transisterized voltage regulators only one running at a time

- Regulates the voltage of both alternators

- Left to right

- In-out-in-out = opens everything

- Heater switch: on, off, blower

- At altitude never need to use blower

- Blower only comes on when gear handle is down

- There is an overheat switch

Deicing and anti-icing

- Glycol on prop and windscreen

- Not FIKI certified so really shouldn't be using it

- POH page 7-46 for fluid-flow endurance

- Windshield: 36 minutes

- Props: 120 min

- Both: 28 minutes

Oxygen System

- No oxygen system in N3622A